At Caledonia Environmental, we recently completed a crucial repair on a BD Biodisc sewage treatment plant in Linlithgow. This particular job was essential because the system hadn’t been serviced in years, leading to several mechanical issues. In this post, we’ll take you through the repair process, highlighting the challenges and the importance of regular servicing to ensure the longevity and efficiency of your BD Biodisc system.

The Problem: Rusted Shaft Clamps and a Broken Shaft

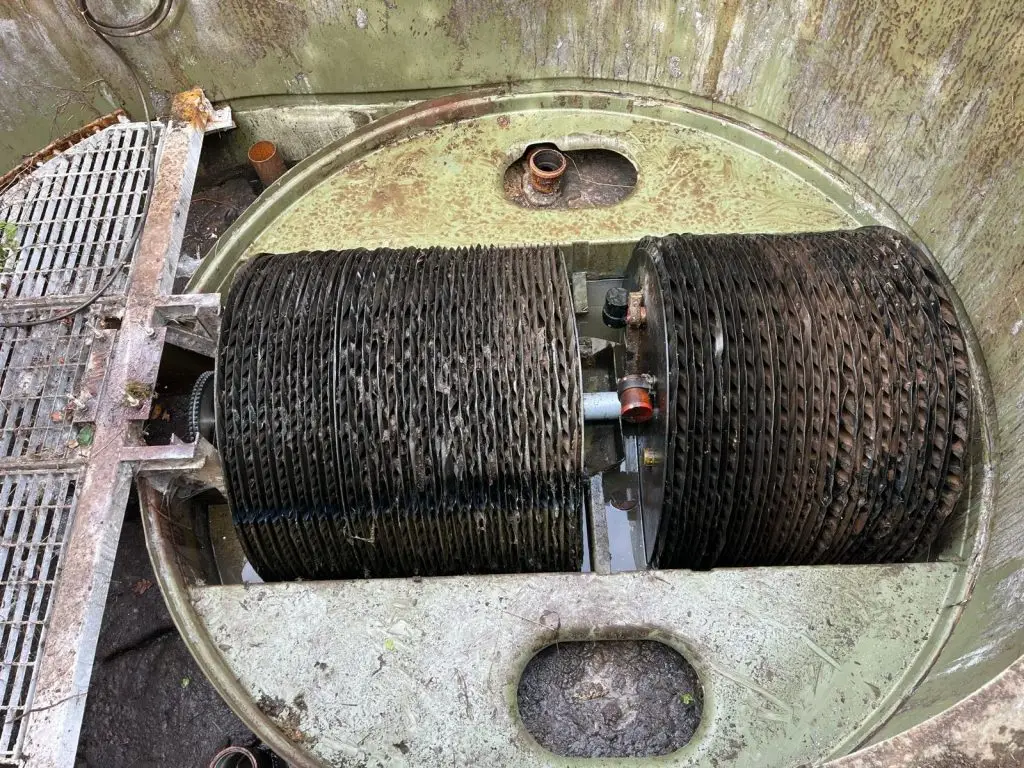

The BD Biodisc system we worked on had not been properly maintained for quite some time, resulting in a number of issues. The shaft clamps had rusted, which meant the drive shaft was turning inside the disc packs. This caused significant wear on the shaft, eventually eating through it and splitting the shaft entirely. Without a properly functioning shaft, the disc packs couldn’t turn as intended, which created a cascade of problems for the rest of the system.

As the shaft struggled to turn on its bearings, the motor gearbox was subjected to increased strain, eventually leading to a motor gearbox failure. These issues created an urgent need for a full restoration.

The Work Involved: A Full Restoration of the BD Biodisc System

Our team at Caledonia Environmental took the following steps to restore the BD Biodisc sewage treatment plant to full working order:

- Lifting the Disc Packs: First, we carefully lifted both disc packs out of the system separately due to the split shaft. This step required attention to detail to prevent any further damage.

- Removing the Old Shaft: After carefully extracting the old shaft, we ensured that the surrounding components were intact and ready for the installation of a new shaft.

- Installing the New Shaft: We then installed a new shaft, making sure it was positioned exactly where the old one had been. Alignment is critical in these repairs, as even slight misalignments can cause further complications down the road.

- Reinstalling the Disc Packs: With the new shaft in place, we used a Manitou to lower both disc packs back into position. This part of the job required both precision and care to ensure everything was secured properly.

- Installing a New Bottom Pulley and Locking Element: To ensure proper functioning, we installed a new bottom pulley along with a locking element to hold the pulley in place securely.

- Replacing the Motor Gearbox and Bearings: The final step involved installing a new motor gearbox, complete with a new top pulley. We also replaced the non-drive end and drive end bearings, which were critical to ensuring the smooth operation of the system.

Conclusion: Why Regular Servicing is Key for BD Biodisc Systems

This repair job in Linlithgow highlights the importance of regular maintenance for BD Biodisc sewage treatment plants. If the system had been serviced on a regular basis, the issues with the shaft, pulley, and motor gearbox could have been prevented, saving both time and money.

If you’re in Linlithgow or the surrounding areas and need professional repair or servicing for your BD Biodisc sewage treatment system, don’t hesitate to get in touch with us at Caledonia Environmental. Our team of trained professionals, experienced with BD Biodisc systems, is here to ensure your system runs smoothly for years to come.